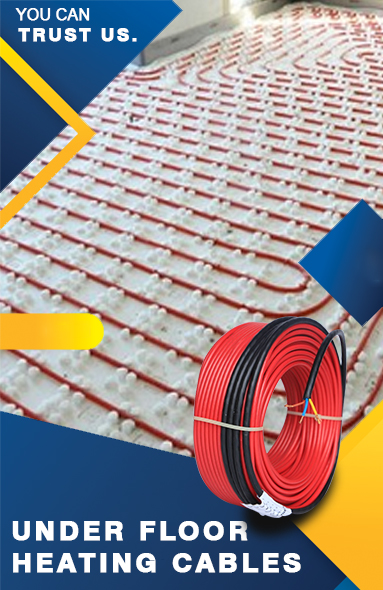

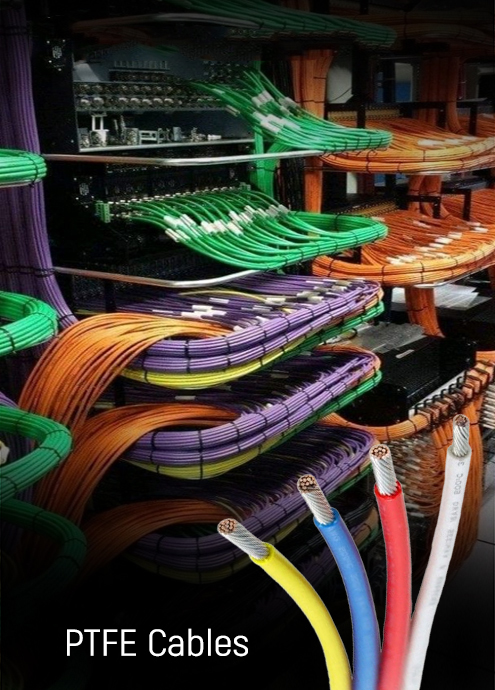

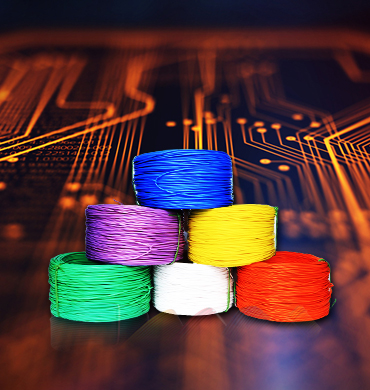

We specialise in a diverse range of High Temperature and Flame Retardant wires and cables, tailored to meet your unique requirements.

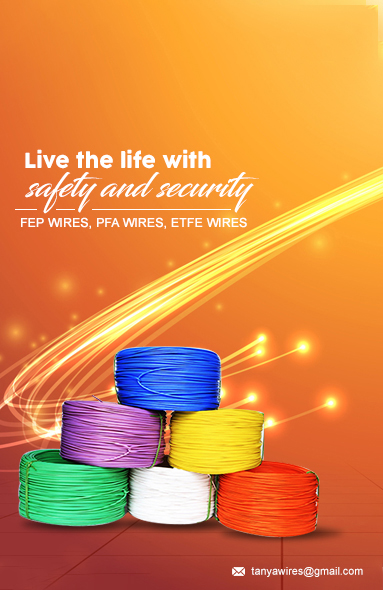

Since 2000, "Tanya Enterprises" has been a pioneering force in high-temperature cable solutions, catering to industries like Defence, Aerospace, and Automobiles. Co-Founded by industry experts Mr. Subhash Chandra Tonk, Mr. Neeraj Kumar Tonk and Mr. Rahul Tonk, we excel in manufacturing Insulated Wires & Cables using premium Fluoropolymers - PTFE, FEP, PFA, and ETFE.